Project Description

Project Details

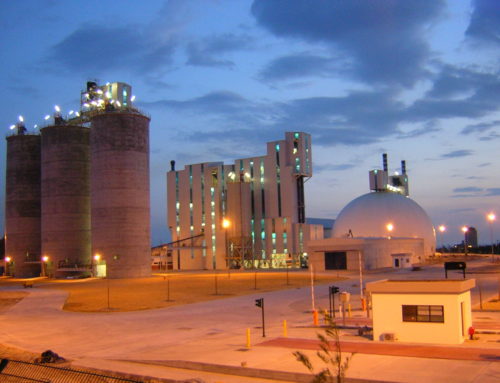

FORNAKA BPAC PIPE PRODUCTION FACTORY

Client : Ministère de Ressources en Eau – ANBT – Agence Nationale de Barrages et Transferts

Location : Mostaganem – Algeria

Year of Completion : 2007

The contract was characterized by the construction of a reinforced concrete tube factory with an incorporated plate core.

Main data:

Land area: 118,000 m2 Earthwork: 128,680 m3

Concrete: 13,060 m3

Steel: 1,100 ton

Metal structure: 1,140 ton

Main structure: 17,100 m2

Secondary bodies: 1,200 m2

Coverage: 19,933 m2

Social facilities: 1,033 m2

Production of 6 meter long tubes

Diameters: Ø 2200 mm, Ø 2000 mm, Ø 1800 mm, Ø 1400 mm

Production capacity: 728 tubes / month (4 km)

Technology and description of main equipment:

Manufacture of the tubes: Casagrande Technology

Machine for making the joints (ends)

Machine for making sheet

core fabrics Circumference welding

machine Hydrostatic testing machine

22 Molds (3 x Ø 2200, 12 x Ø 2000, 2 x Ø 1400)

Dump truck

2 Strapping

machines 2 Coating

machines Tube deflection testing machine

6 Cranes with boom

Concrete production: Simem concrete

plant Maximum plant capacity: 175 m3/h

3 Mixers (2 x 2500 lts + 1 x 1500 lts)

5 100 ton silos each

Shuttle system for feeding the molds

Elevation means: Jaso

2 40 ton

cranes 3 40 ton cranes

4 32 ton cranes

1 16 ton crane

2 5 ton cranes

Mains:

Power: 2250 kVA (2 transformers of 1250 kVA and 1 of 1000 kVA)

Emergency generator set, consisting of 2 generator sets of 1000 kVA and 1 generator set of 100 kVA

Compressed air network: Atlas Copco GA110 compressor (19 m3/min)

3 tanks of 3 m3 each

Steam production:

2 boilers with installed power of 20 KW

Water / sanitation / fire network:

Independent rainwater and wastewater sanitation system

Domestic water treatment plant Oil

separation plant

Concrete laboratory